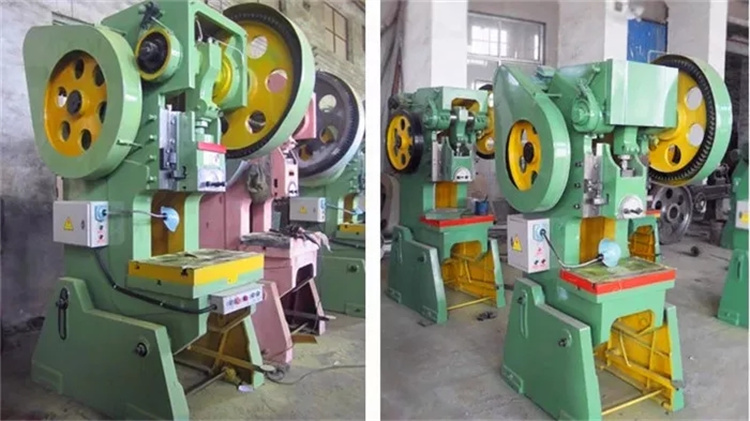

Scope of application:

The multifunctional combined punching and shearing machine is a manual punching and shearing equipment that integrates cutting, shearing, punching, plate shearing and angle shearing. It uses overlapping two-stage levers, sliders, crankshafts, etc. to drive a 5-station The sliding board moves up and down to achieve a multi-purpose effect. It is widely used in machining, construction, electric power, railway, shipbuilding, automobile and other industries.

Productparameters

| Model | QJ-8B | QJ-10B | QJ-12B |

| Shear force | 360KN | 500KN | 900KN |

| Tool stroke | 27MM | 30MM | 36MM |

| Number of trips | 30Times/min | 30Times/min | 30Times/min |

| Motorkracht | 2.2KW/380V | 3.0KW/380V | 4.0KW/380V |

| Machine gewicht | 550KG | 700KG | 1100KG |

| Dimensies | 900*600*1100MM | 900*600*1250MM | 1100*600*1450MM |

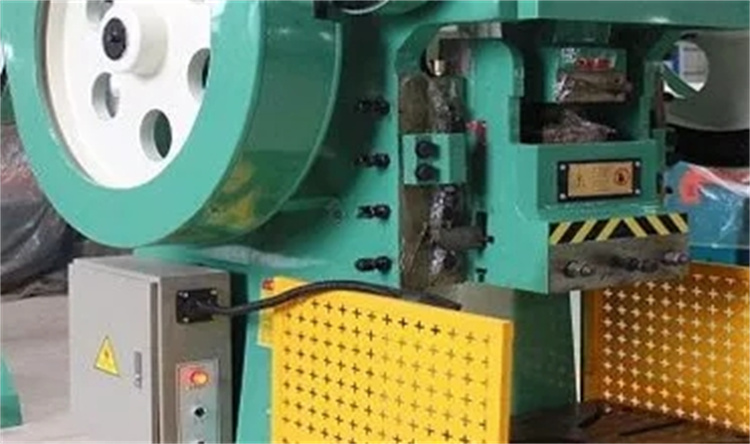

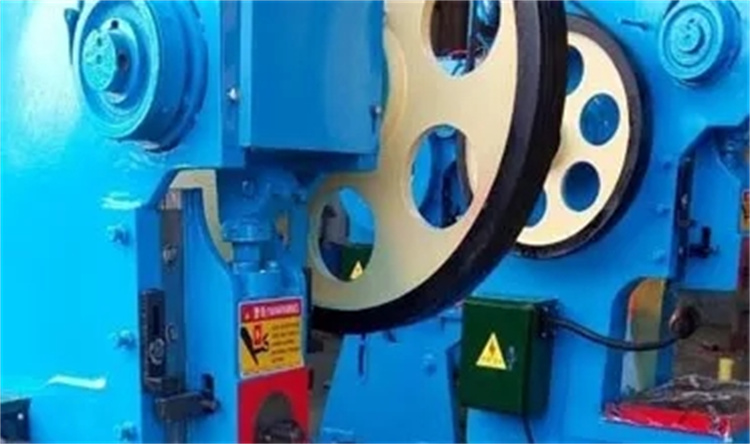

Machine Part

Machine body

Use rod tightening combination frame structure, with sufficient strength and rigidity;The slider uses rail guide; machine and slider are welded steel, the material is Q235-A, using carbon dioxide gas shielded arc welding, the weld should be ground smooth, no weld slag and streaming scars, remove inner stress after weld.

Oil Cylinder

Solo cylinder structure which is disposed on the upper beam hole, cylinder block uses 45 # forged steel.

Plunger rod surface hardening hardness is HRC45-50. The cylinder finishing by high-precision machine tools, cylinder bore after refining process to increase surface hardness and wear resistance.

Bliwing Cylinder

Domestic famous engines, strong driving force, low fuel consumption, high economic benefits 12F+4R sliding sleeve shift.

Oil Cylinder

Solo cylinder structure which is disposed on the upper beam hole, cylinder block uses 45 # forged steel.

Plunger rod surface hardening hardness is HRC45-50. The cylinder finishing by high-precision machine tools, cylinder bore after refining process to increase surface hardness and wear resistance.

Our Company